Device model :DC01-JY01

Test space:300x300x300mm(L x W x H)

Dimension:700x800x1830mm(L x W x H)

Weight:about 220kg

▊ Product introduction

The battery needle extrusion tester is suitable for simulating various types of batteries when they are squeezed during use, transportation, storage or disposal of household waste. The battery should not explode or catch fire. The battery extrusion testing machine conforms to GB31241-2014 and other standards.

▊ Typical application

Battery needle extrusion tester is suitable for simulating various types of batteries in the use, transportation, storage process, the battery is squeezed and punctured.

▊ Application industries: battery industry, new energy power, electrochemical energy storage industries, etc.

▊ Product functions

The extrusion direction of the extrusion test should follow the following rules: a battery is only squeezed once, and the battery is qualified without explosion or fire.

1. For cylindrical batteries, the vertical axis of the acupuncture battery should be parallel to the two plates of the extrusion device

2. For square and soft pack batteries, only the wide side of the battery is needled

3. For the coin or button battery, the upper and lower planes of the battery are parallel to the plate

The acupuncture test should be carried out at 20 ° C ±5 ° C. The battery should be placed flat on the fixture, and the non-corroded steel needle with a diameter of 3-8mm should be inserted into the center of the battery surface at a speed of 10mm/ S-40mm /s, and the test results should be kept for any time and observed. The battery should not explode or catch fire. The battery extrusion testing machine conforms to GB31241-2014 and other standards

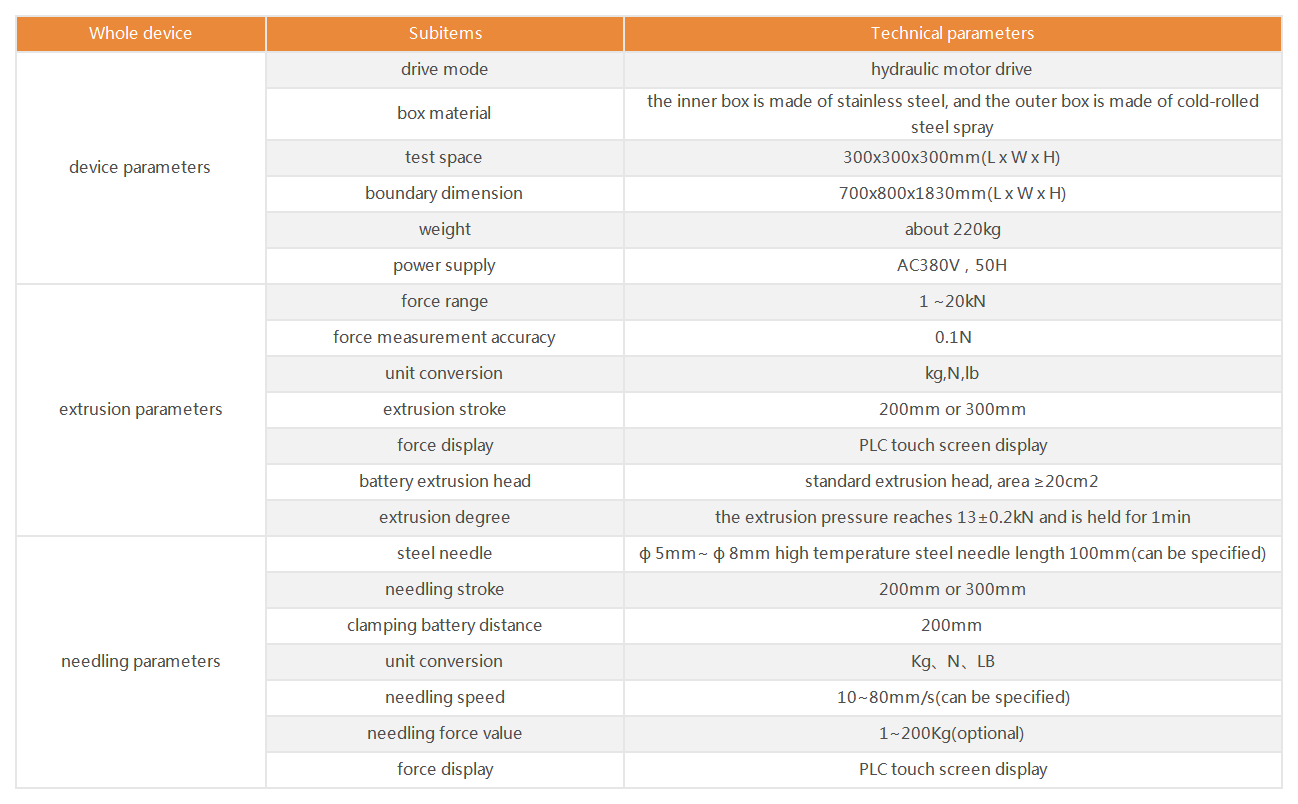

▊ Product Parameters