更新时间:2024-07-25浏览量:58

【EXHIBITION】

On the morning of July 20, the ninth National Energy Storage Engineering Conference was grand opened in Kaifeng Sheraton Hotel. More than 1,000 representatives from universities, research institutes and related enterprises gathered here to discuss and exchange the latest research progress and technical achievements in the field of energy storage.

The conference was co-sponsored by Henan University, the Energy Storage Engineering Committee of Chemical Industry Society of China, the Institute of Nano Science and Engineering of Henan University, the Longzihu New Energy Laboratory, the State Key Laboratory of Powder Metallurgy of Central South University, the School of Environmental Engineering of Henan University of Technology, etc. The opening ceremony was presided over by Professor Zhang Jingwei of Henan University. Academician Zhang Suojiang, President of Henan University, Academician Pan Fusheng of Chongqing University and Professor Ma Zifeng of Shanghai Jiao Tong University delivered speeches at the opening ceremony. In the report session of the conference, Academician Yang Chunhe of Wuhan Institute of Rock and Soil Mechanics, Chinese Academy of Sciences, and Academician Xu Chunming of China University of Petroleum (Beijing) made a report on the opening ceremony.

The theme of this conference is "Efficient conversion - Green energy storage - Circular development", and the experts and scholars attending the conference discussed important topics such as "energy storage safety and operation", "energy storage material technology and strategic emerging industry development", "electrochemical energy storage," physical energy storage ", "hydrogen storage and fuel cell technology" from a professional perspective.

【Stone focusing】

During the conference, an endless stream of experts and scholars stopped to visit the booth No. 19 of Dianshi Instrument and exchanged views on the advanced technology , application direction and cooperation experience of star exhibits such as "Battery Comprehensive Performance Experiment Module", "fixed volume bomb" and "Tabletop Heat Island".

【Energy storage safety test equipment】

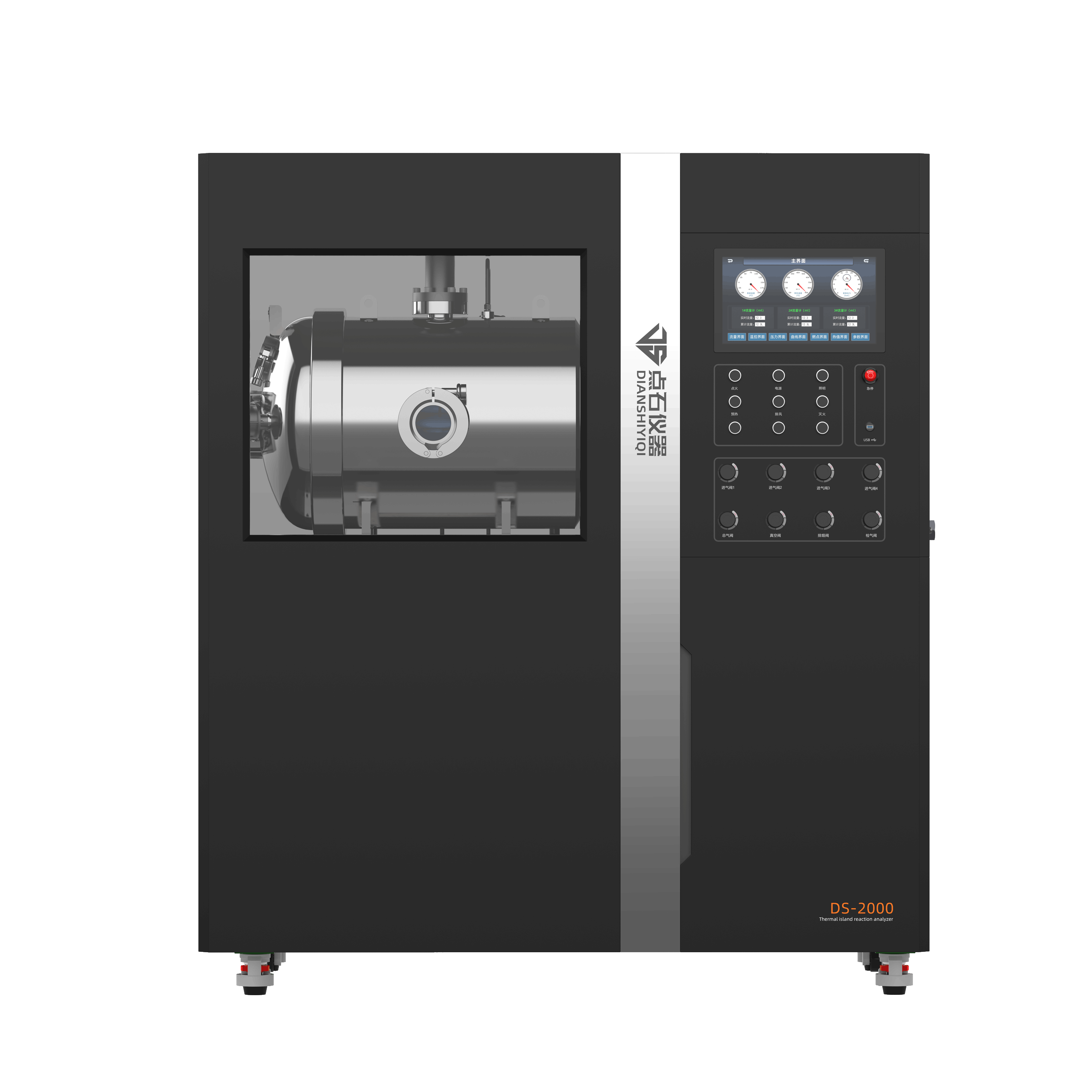

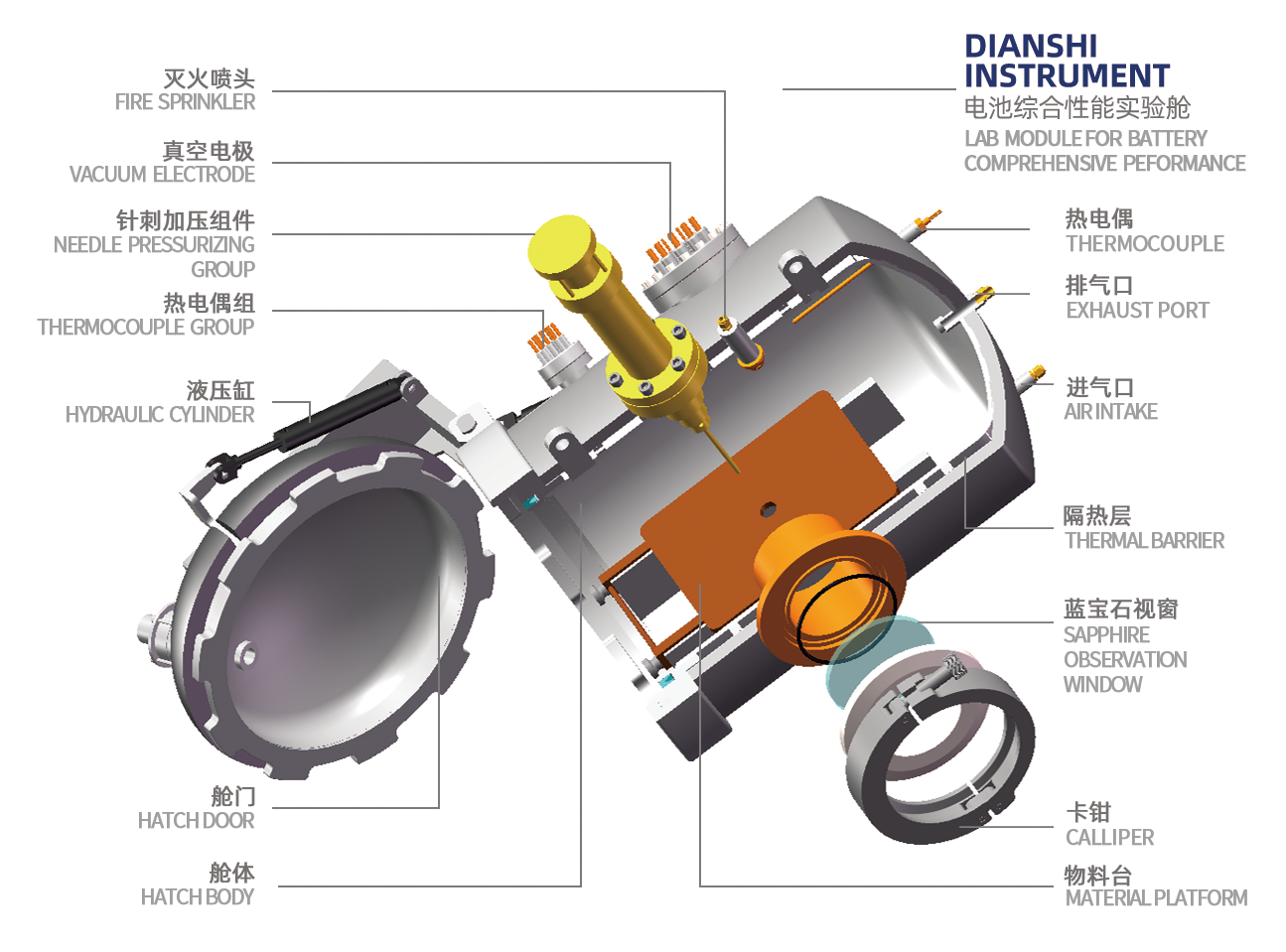

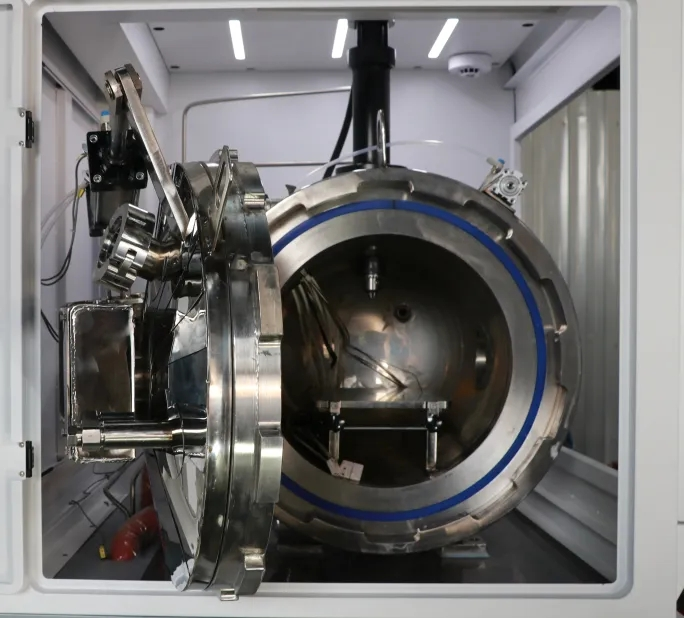

01 Battery comprehensive performance experiment room

The battery comprehensive performance laboratory can realize the coupling of a variety of environmental factors (temperature, pressure, atmosphere, etc.), and carry out a variety of tests on the battery (acupuncture, extrusion, overcharge, overdischarge, short circuit, temperature cycle, ignition, fire extinguishing), which is used for the comprehensive performance test of the battery cell and small battery modules.

High temperature environment:

Overall maximum ambient temperature: 100℃, heating rate 1℃/min

Maximum temperature of local table: 600℃

Maximum temperature rise rate: 10℃/min

According to standards: GB/T 2423.2-2008, IEC60068

Low temperature environment:

Minimum temperature: -50℃, cooling rate 1℃/min

According to standards: GB/T 2423.1-2008, GB/T 38031-2020

High altitude environment:

Minimum air pressure: 1kPa (A) (approximately 31200m above sea level)

Vacuum time: ≤9min

According to standard: GB/T 31467.3-2015

Acupuncture extrusion:

Maximum extrusion pressure: 20kN, maximum stroke: 100mm

Product analysis:

Online analysis of O2, CO, CO2, SO2, NH3, CH4, C2H4, H2, etc

【cooperative project】

Battery comprehensive performance experiment module delivered to Henan university

02 Walk-in integrated laboratory module

The walk-in integrated laboratory room can build a composite experimental environment (high temperature, low temperature, high altitude, salt spray) for temperature cycle experiments, corrosion resistance experiments, reliability experiments of large parts, and thermal runaway experiments of batteries.

High temperature environment:

Overall maximum ambient temperature: 85℃

Heating rate: 1℃/min

Maximum temperature of local table: 600℃

Maximum temperature rise rate: 10℃/min

According to standards: GB/T 2423.2-2008, IEC60068

low-temperature environment

Minimum temperature: -50℃, cooling rate 1℃/min

According to standards: GB/T 2423.1-2008, GB/T 38031-2020

High altitude environment:

Minimum air pressure: 55kPa (A) (approximately 4850m above sea level)

According to standard: GB/T 31467.3-2015

salt-spray environment

Brine concentration: 5±0.1%, pH value: 6.5~7.2

Brine temperature: 35±1℃

According to standard: GB/T 2423.18-2021

03 Laser igniter

The laser igniter has the advantages of good cold start performance, adjustable ignition position, ignition time and controlled ignition energy, etc. It is used for the ignition, detonation and combustion tests of gas, liquid and solid (battery thermal runaway test, solid propellant ignition test, magnesium aluminum powder ignition test, coal particle ignition test).

【cooperative project】

Laser igniter delivered to Shaanxi university

【Energy storage raw material test equipment】

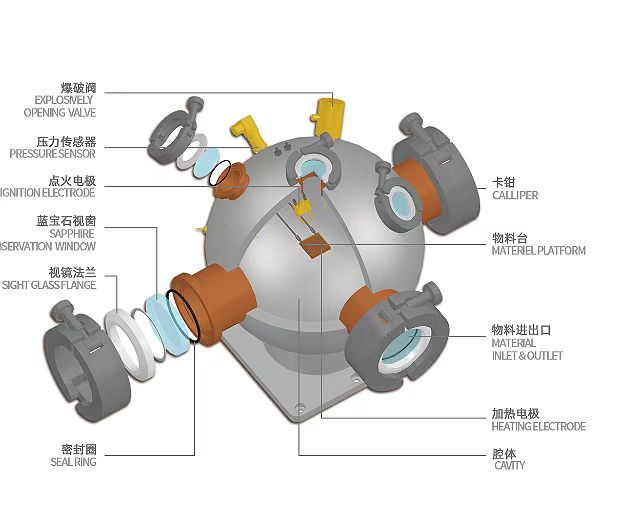

04 constant volume cartridge

The constant volume bomb can test the blasting characteristics of materials under different temperature, pressure and atmosphere environment, and can monitor and observe the experimental process in real time, support data collection and product analysis, and be used for laminar combustion, turbulent combustion, one-time combustion and continuous combustion research.

High-pressure environment:

Maximum working pressure: 10MPa

Vacuum environment:

Limit vacuum degree: 10Pa(A), vacuum time: ≤5min

Schlieren system:

Main mirror optical material: K9 optical glass; Stress: ≤2; Machining surface accuracy: < 1/10Λ; Reflection coefficient: ≥90; Surface accuracy: < 1/10 wavelength

Product analysis:

Online analysis of O2, CO, CO2, SO2, NH3, CH4, C2H4, H2 and other components

According to standards: ASTM E918, ASTM E2079, EN1839, EN15967, UL9540A

【cooperative project】

Fixed capacity ammunition delivered to BYD, Liaoning universities, Sichuan universities

05 Desktop heat island

The desktop heat island can build a composite experimental environment (high temperature, low temperature, high pressure, low pressure, oxygen rich, oxygen poor), and carry out real-time monitoring, observation and record of the experimental process and product analysis, and obtain key parameters (ignition point, calorific value, mass loss, product composition) for the combustion or pyrolysis characteristics of materials.

High-pressure environment:

Maximum working pressure: 3MPa

Vacuum environment:

Limit vacuum degree: 10Pa(A), vacuum time: ≤5min

High and low temperature:

Temperature range: -50℃~+100℃, rising and cooling rate: 1℃/min

Sample preheating:

Maximum temperature: 600℃, maximum temperature rise rate: 20℃/min

Window closes:

Pneumatic opening device, convenient operation

Product analysis:

Online analysis of O2, CO, CO2, SO2, NH3, CH4, C2H4, H2 and other components

According to standards: ASTM E918, ASTM E2079, EN1839, EN15967, UL9540A

【cooperative project】

The desktop heat island is delivered to universities in Hubei and Beijing

As a supplier of customized solutions for energy storage experiments, Dianshi Instrument has always focused on cutting-edge technology, independently developed a number of series of advanced instruments and equipment for energy storage safety testing and energy storage material testing, and is committed to boosting the development of the energy storage industry chain, sponsoring the National energy storage Engineering Conference for two consecutive years (the eighth and ninth), providing strong support for the smooth holding of the energy storage conference.