更新时间:2025-05-07浏览量:31

[I. Article Introduction]

Heavy fuel oil (HFO) has become the main fuel for Marine diesel engines due to its high calorific value and low price. Its composition is extremely complex, mainly consisting of alkanes, aromatic hydrocarbons, asphaltenes, and a small amount of metals and sulfides. To reduce the emission of sulfur oxides, the sulfur content in Hfos is strictly limited. Due to the influence of raw material origin and production technology in the production of low-sulfur HFO, there are significant differences in its physical and chemical properties. These differences will have an important impact on fuel spraying, combustion processes and pollutant formation.

Marine two-stroke diesel engines widely use HFO as fuel. Four-stroke diesel engines are often used in the propulsion systems of medium and small-sized ships or as prime movers for power generation in large ships. To save fuel costs, this type of four-stroke diesel engine often uses HFO as fuel. Unlike large two-stroke diesel engines, four-stroke diesel engines have smaller injector hole diameters and higher injection pressures. Moreover, four-stroke diesel engines are usually designed for burning diesel. In recent years, scholars believe that changing the injection conditions can improve thermal efficiency and reduce emissions, and the injection conditions continue to develop towards high pressure - micropores. The spray and ignition characteristics of HFO under high-pressure - microporous conditions require attention. However, most current studies focus on analyzing the influence of HFO on engine performance and emissions, while there are few reports on the spray and combustion characteristics of HFO. Existing studies mainly focus on the spraying of HFO while ignoring the ignition and combustion processes, and HFO may have different physical properties.

Based on this, the author took Hfos of various viscosities and sulfur contents as the objects and conducted research on the spray and ignition characteristics of Hfos under the conditions of high injection pressure and micro-pore injection. Firstly, the multi-condition CVCC model was established and verified based on the optical test data; Secondly, taking three Hfos with highly representative viscosities as the research objects, the influence of fuel physical properties on the spray and ignition characteristics was analyzed; Meanwhile, the influence of oxidation on the spray development was studied under different environmental conditions, with the expectation of providing a reference for the efficient and clean application of HFO in four-stroke Marine diesel engines.

【 II. Model Verification and Research Conditions of the Test Device 】

Test device

The experiment was carried out on the latest generation of CVCC of ECN. The environmental conditions of this device cover the vast majority of diesel engine operating conditions. The environmental temperature is 450-1,300 K, the environmental density is 3-60 kg/m³, and the environmental oxygen volume fraction is 0% - 21%. The effective volume of CVCC is 1.15L, and it creates high-temperature and high-pressure environmental conditions by burning combustible mixed gas. The injection system is suitable for a variety of fuels, with a maximum injection pressure of 150 MPa and a maximum nozzle diameter of 0.5 mm. The four working conditions of the test are shown in Table 1, and a single-hole injector with a spray hole diameter of 0.09mm is used. The injection pressure is 150 MPa, the injection duration is 1.54 ms, and a single injection of 3.46 mg of n-dodecane. In the experiment, various optical observation methods were adopted for different working conditions to obtain parameters such as the liquid phase spray penetration distance (LPL), the gas phase spray penetration distance (VPL), the flame rise length (FLOL), the ignition time (IT), and the flame morphology.

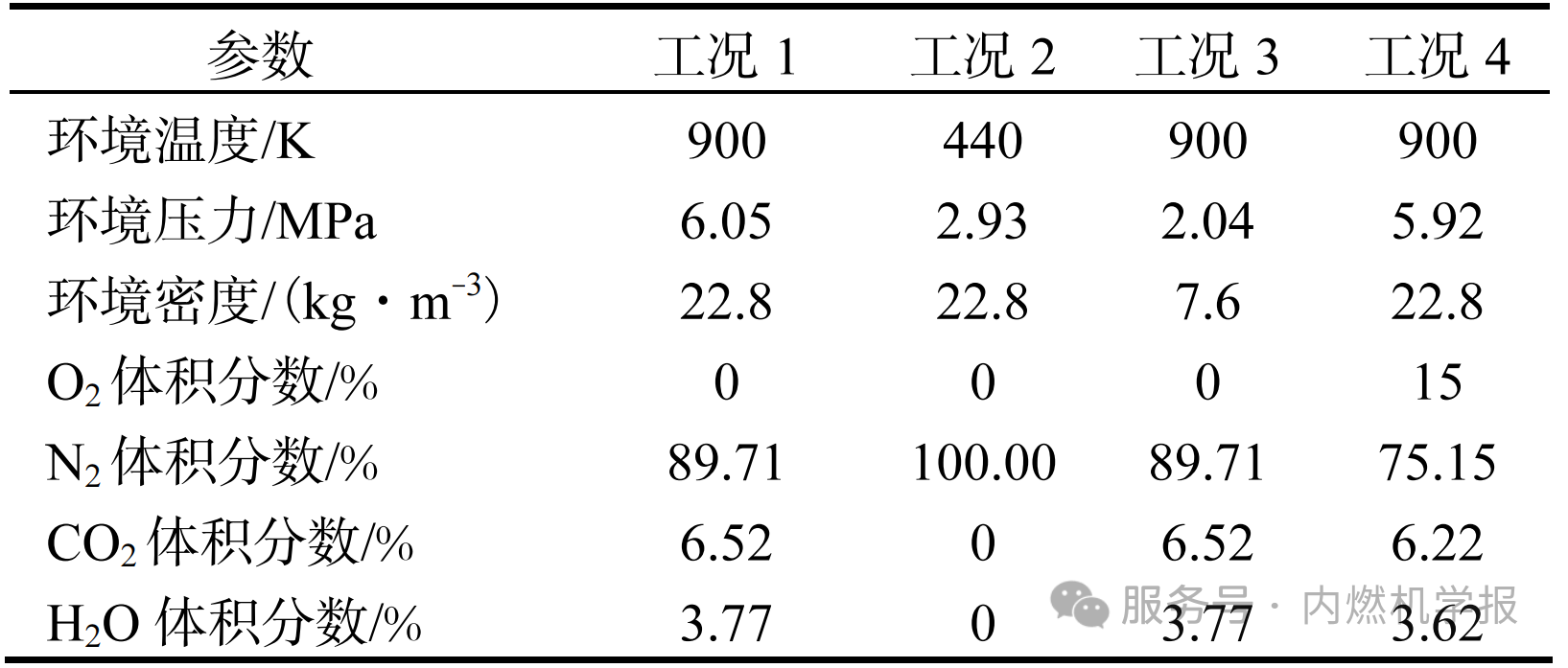

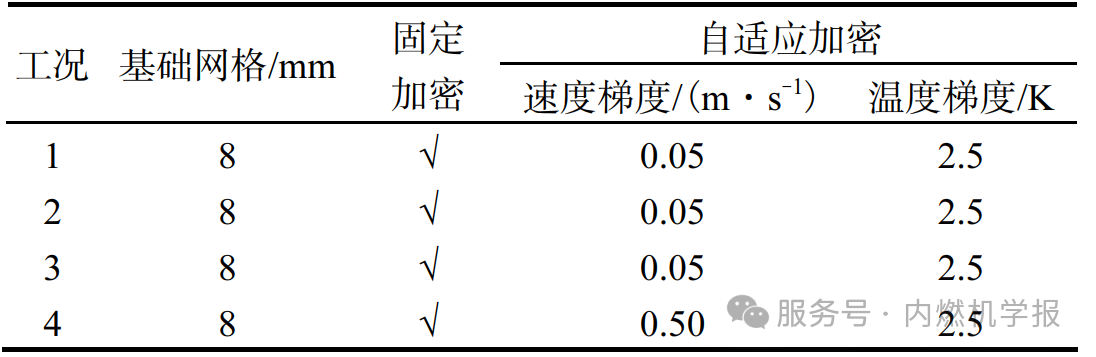

Table 1 Environmental Conditions and Injection Conditions

Establishment and verification of the model

Model establishment:

The author established the CVCC model and verified the model under four working conditions using Converge. The basic grid size is 8 mm. Table 2 shows the grid Settings and encryption strategies. The minimum grid size after grid encryption is 0.0625 mm. A 7-level fixed encryption is carried out near the spray holes, and a 7-level adaptive encryption is implemented according to the speed and temperature gradients. Figure 1 shows the geometric model dimensions and encryption effect of CVCC. The detailed chemical reaction mechanisms of 163 components and 887 reactions were used in combination with the SAGE chemical kinetics solver to describe the chemical reactions during fuel oxidation, ignition and combustion. The fuel crushing process is described by KH-RT, where the model constants B0 and B1 take values of 0.61 and 50 respectively. Both Large Eddy Simulation (LES) and Reynolds Mean (RANS) can describe the turbulent motion during the spray process more accurately. However, under high spray pressure conditions, LES has better transient accuracy. Therefore, the author uses LES to solve the turbulent motion involved in the spray and combustion processes. The mass fractions of liquid fuel at 90% and gaseous fuel at 0.1% were respectively adopted as the thresholds for calculating LPL and VPL. In the study, LPL uses the recommended value of ECN, while VPL is calculated based on the density gradient. After differentiating the density to obtain the slices with the density gradient, the maximum vertical distance between the edge of the density gradient image and the nozzle is obtained through image processing and recognition. The advantage of using density gradient statistics (VPL) lies in that it is closer to the principle of sternography technology. Meanwhile, it can avoid the fluctuations and errors caused by the statistics of VPL based on the mass fraction threshold in the simulation calculation due to combustion. The moment corresponding to half of the maximum chemiluminescence intensity of combustion is defined as IT. The position of the flame is represented by the chemical fluorescence of OH*, and the shortest distance between the flame and the nozzle is defined as FLOL.

Table 2 Grid Settings and Encryption

Figure 1 Geometric model and mesh refinement

Model validation

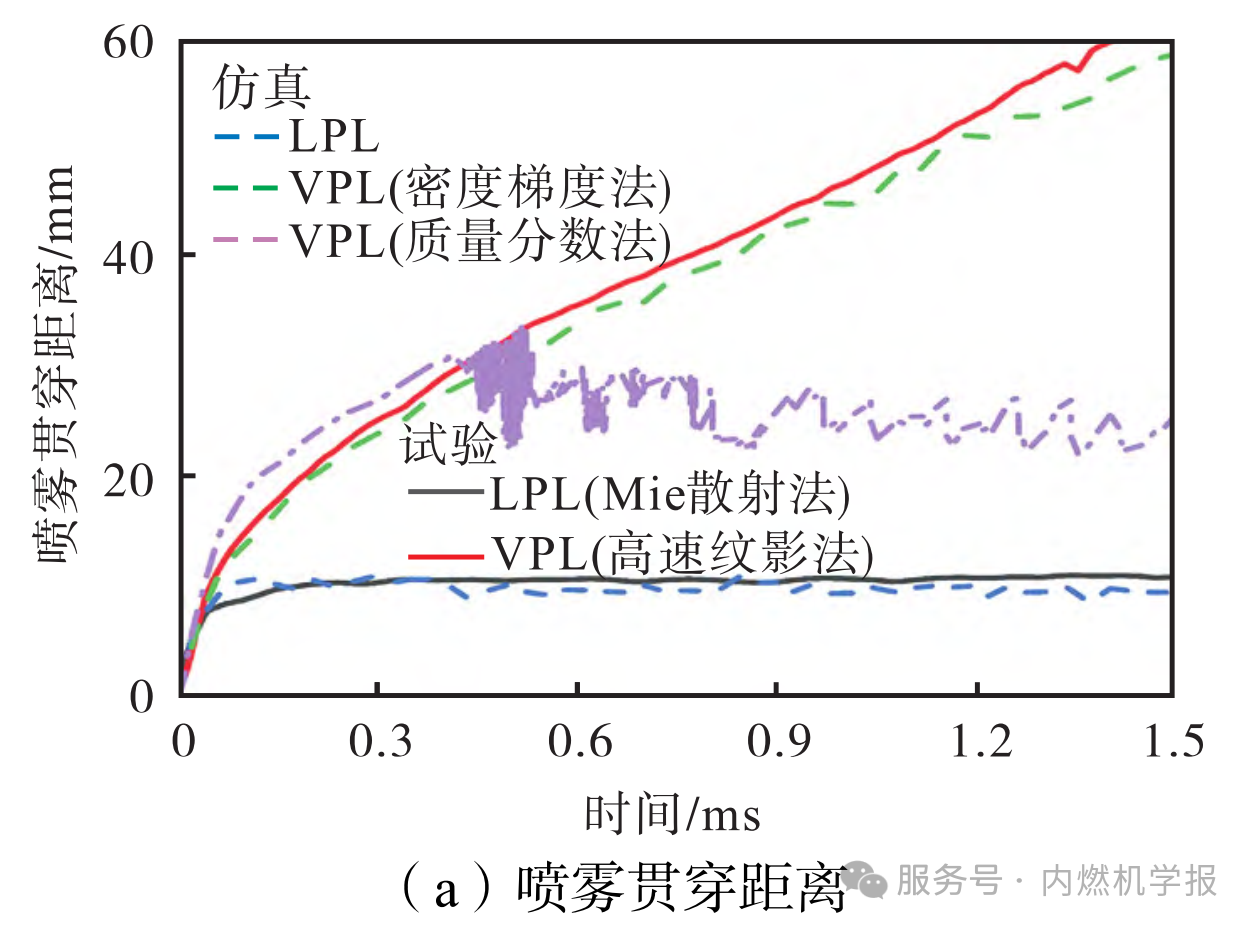

VPL and LPL are respectively the maximum vertical distances from the corresponding thresholds to the nozzles, characterizing the penetration ability of the fuel jet. In the experiment, the VPL and LPL of the spray were obtained by using the high-speed ripple method, the diffusion background imaging method and the Mie scattering method. In the simulation, the VPL and LPL were obtained by using the mass fraction method and the density gradient method. Figure 2 shows the verification of the CVCC model under working conditions 1, 2 and 3. This model can describe the injection and atomization processes of fuel under non-reactive conditions quite well.

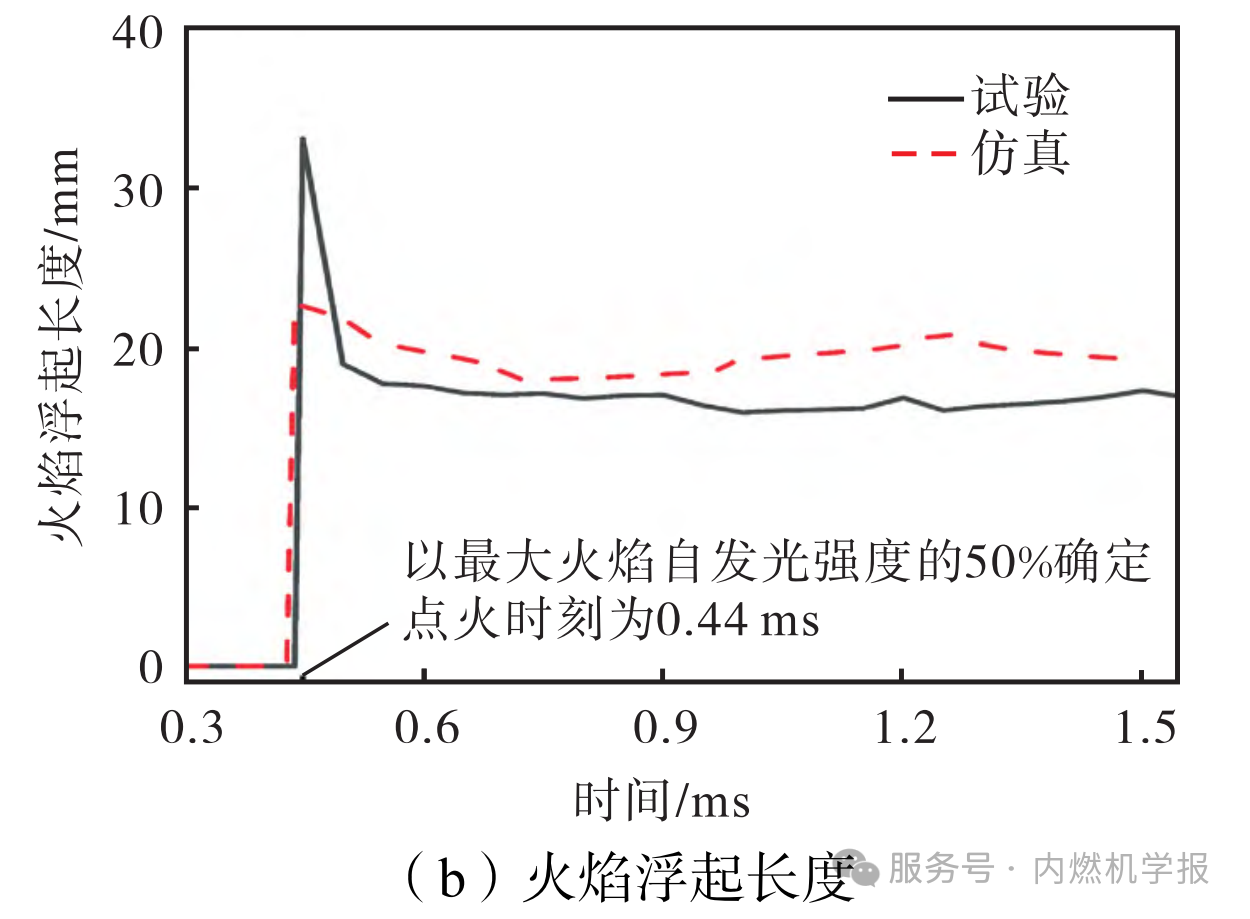

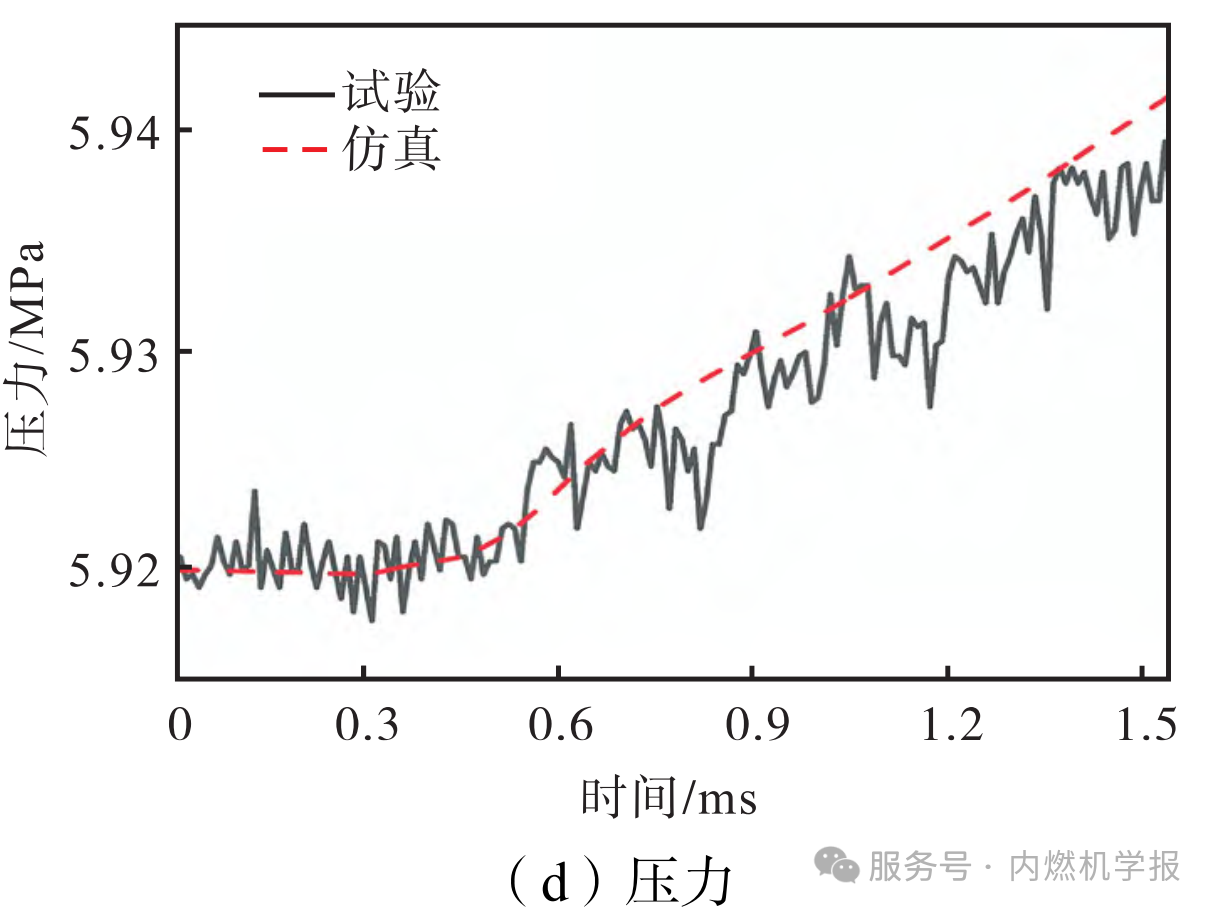

Figures 3 and 4 show the verification of the spray penetration distance, combustion parameters and flame morphology under reaction conditions (containing oxygen). The LPL verification result of working condition 4 in Figure 3 is relatively good. The degree of consistency among the pressure inside the cylinder, the cumulative heat release and FLOL is excellent. During the entire combustion process, the pressure fluctuation within the constant-volume combustion projectile is extremely small (0.02 MPa), and the cumulative heat release is approximately 75 J. The variation trends and errors of the in-cylinder pressure, cumulative heat release and steady-state FLOL(with a OH* mass fraction threshold of 0.03%) are all within the acceptable range.

Figure 3 Model verification of working Condition 4

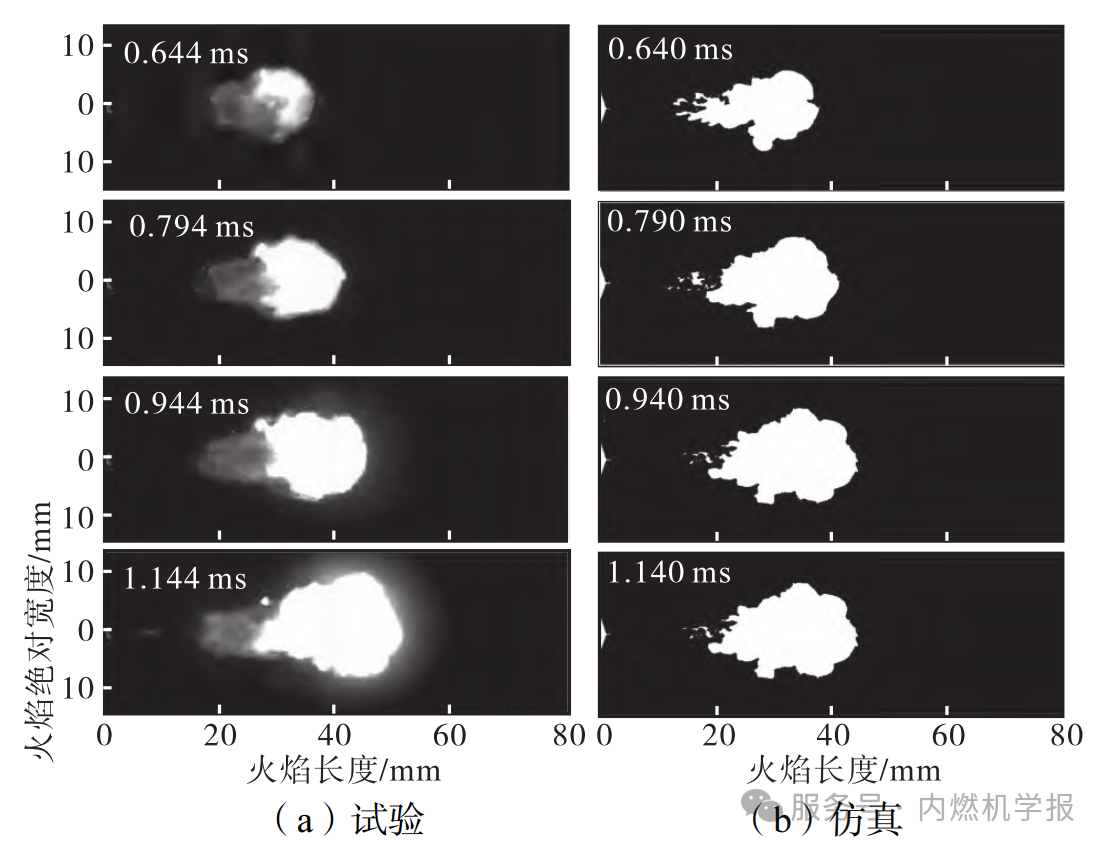

Figure 4 Flame morphology verification of working condition 4

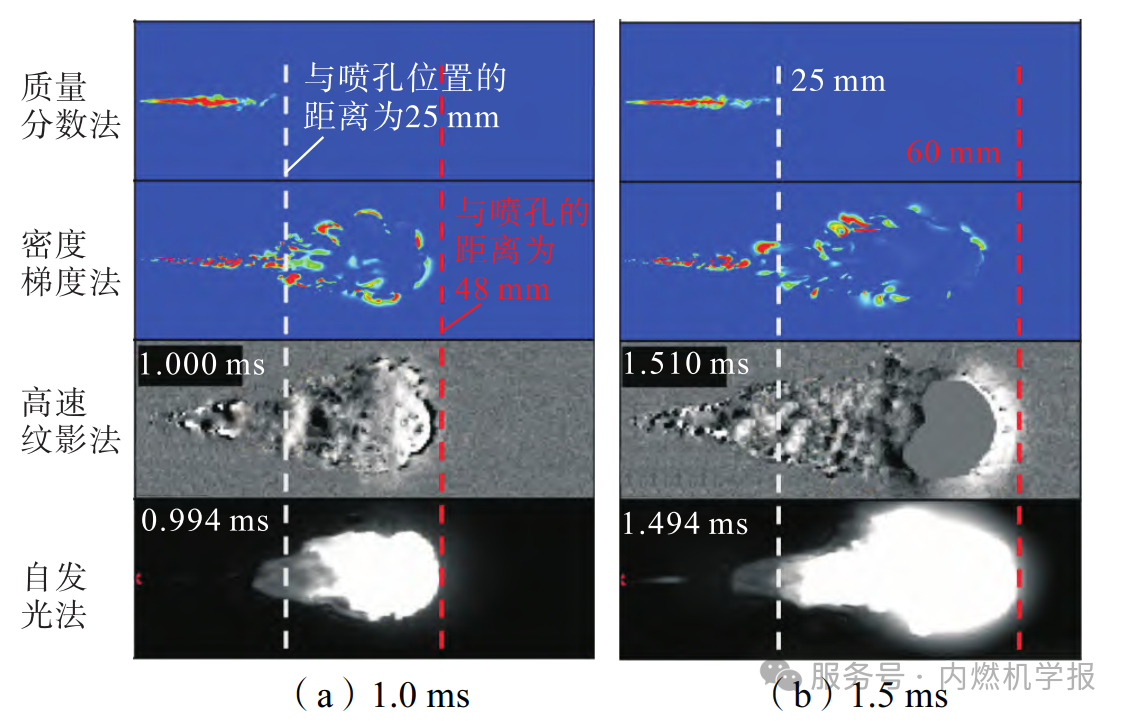

Figure 4 shows the comparison of the characterized combustion flame morphology and the self-luminous flame images in the area above 1,600 K. It can be known that the length, width and area of the flame, as well as the distance between the upstream of the flame (close to the nozzle) and the nozzle, all have a good similarity with the test. However, the verification results of VPL in Figure 3(a) indicate that there are significant differences in VPL obtained by the mass fraction method and the density gradient method. The VPL obtained by the high-speed ripple method and the density gradient method increases over time, while the VPL obtained by the mass fraction method remains dynamically stable after combustion. The main reason is that the mass fraction of the gas-phase fuel in the flame area is lower than the threshold due to combustion consumption and is not statistically analyzed. In addition, actions such as oxidation and pyrolysis cause the statistical target to evolve into other components.

Figure 5 shows the comparison of the gas-phase spray morphology obtained by the mass fraction method and the density gradient method with the experimental streak image and the self-luminous flame image. In fact, after the fire, the spray continued to penetrate forward, and the penetration speed was close to that of the non-burning spray. Using the density gradient method to calculate VPL is more in line with reality than the mass fraction method. In conclusion, the validity of the model has been well verified and it can be used to carry out further research work.

Figure 5 Comparison of gas-phase spray treated by different simulation methods with experiments

Research conditions

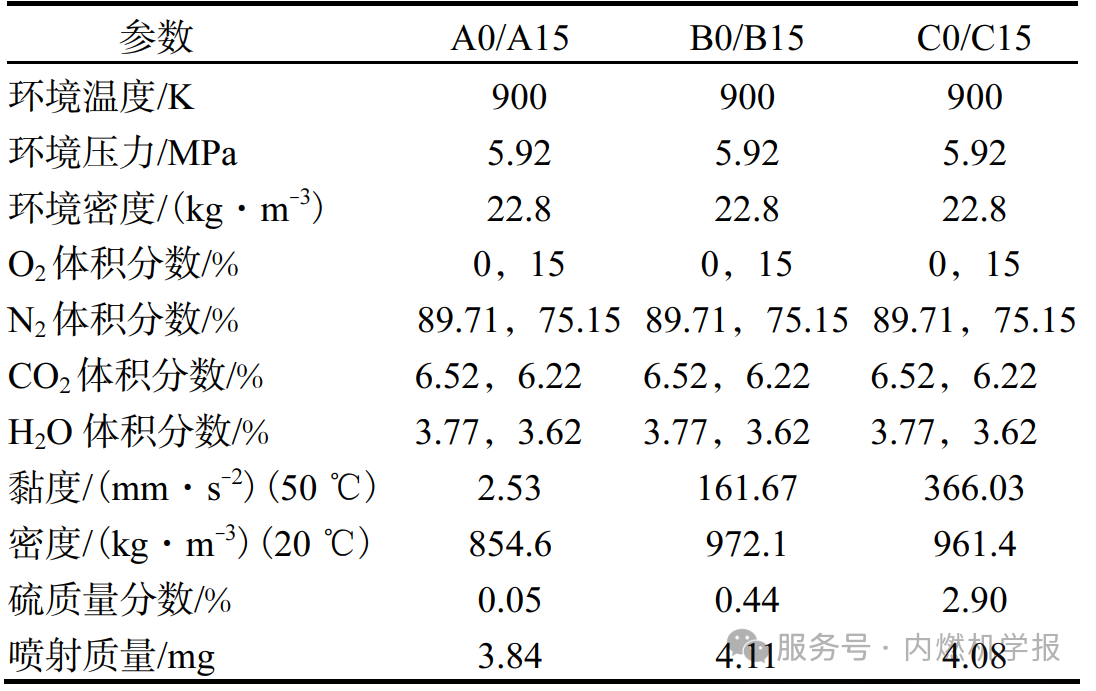

Sprays are classified into non-reactive sprays under anaerobic conditions and reactive sprays under oxygen-containing conditions based on whether combustion occurs. The properties of the fuel used by the author, the initial conditions within the CVCC and the injection conditions are shown in Table 3. Three Hfos with highly representative sulfur mass fraction, density and viscosity were used in the study. The viscosity and density of fuel fluctuate with the mass fraction of sulfur. Among them, the maximum difference in density is 12.1%, and the difference in viscosity is 144 times. Number HFO from fuel A to C in ascending order of viscosity (mass fraction of sulfur).

Table 3 Properties of Fuel, Initial and Injection Conditions

According to the viscosity-temperature characteristic curve obtained from the experiment, the HFO temperature was set to ensure that the viscosity of HFO was consistent with that of nC12H26. The diameter of the nozzle, the injection pressure and the injection duration remained unchanged (0.09 mm, 150 MPa and 1.54 ms respectively), and the injection quality was adjusted to eliminate the change in injection characteristics caused by the density difference. To explore the influence of chemical reactions on the spray development process, spray experiments and simulation studies were conducted under different environmental conditions. Adjust the proportion of components to obtain the environmental oxygen volume fractions of 0% and 15% under the same initial conditions (temperature, pressure and density). The examples are named based on the volume fractions of fuel and oxygen. A0 represents the combination of fuel A and an environmental oxygen volume fraction of 0%.

[III. Analysis and Discussion]

Spray characteristics

A series of complex physical and chemical processes that fuel undergoes after leaving the nozzle jointly determine the development of the spray. Figure 6 shows the development of the spray under different environmental conditions (oxygen volume fractions of 0% and 15%). LPL and VPL separate rapidly after leaving the nozzle. LPL reaches stability in a short period of time and stops penetrating until the end of the spraying, while VPL continues to penetrate forward throughout the entire spraying process. The VPL of low-viscosity fuel is relatively low, while that of high-viscosity fuel is relatively high. The difference in VPL increases due to combustion. Under the condition of oxidation, the penetration ability of low-viscosity HFO is significantly weakened. The injection rate equal to the evaporation rate and the combustion rate equal to the mixing rate are the two quasi-steady-state stages of liquid fuel jet and combustion. These two quasi-steady-state stages are jointly affected by fuel properties and environmental conditions, resulting in the differences between LPL and VPL. The ratios of the spray penetration distances under reaction and non-reaction conditions are shown in Figures 6(c) and 6(d). The influence of combustion on the spray development is significant. The closer the ratio of LPL under reaction conditions to that under non-reaction conditions is to 1, the smaller the influence of oxidation on the development of the spray. Oxidation has an impact on both LPL and VPL, but the degrees are different. Before ignition, LPL is not affected by oxidation. Combustion before the end of injection will weaken the axial penetration ability of the droplets. Compared with LPL, the influence of oxidation on VPL is extremely obvious, especially after the occurrence of fire. With the continuous progress of combustion, VPL is increasingly affected by the oxidation reaction, and the lower the viscosity of HFO, the greater the impact it is affected by. The gas-phase penetration ability of high-viscosity HFO is stronger, and it slightly decreases and quickly recovers after ignition. The penetration ability of low-viscosity HFO significantly decreases after ignition. It indicates that the evaporation, diffusion and mixing of high-viscosity HFO are poor.

Figure 6 Spray penetration parameters under different oxygen volume fractions

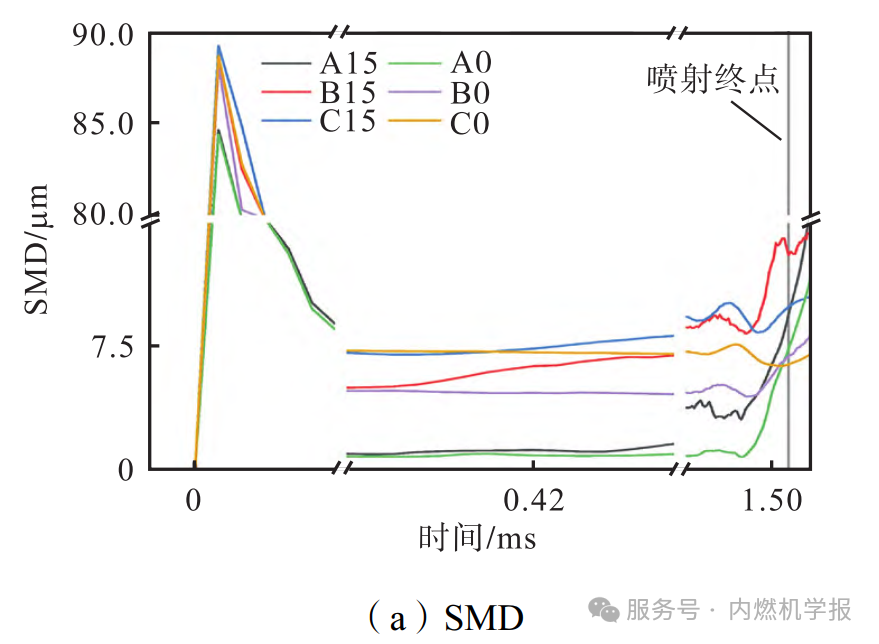

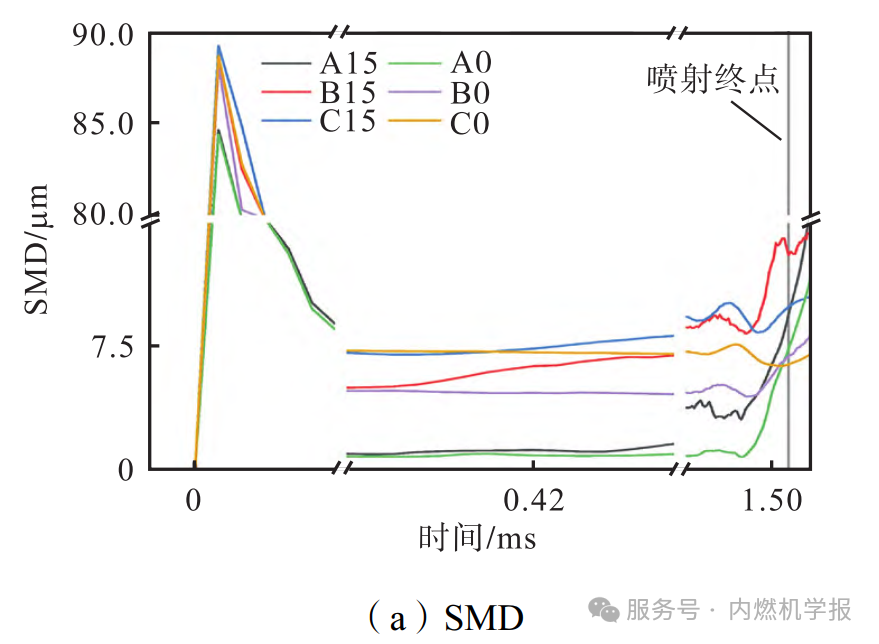

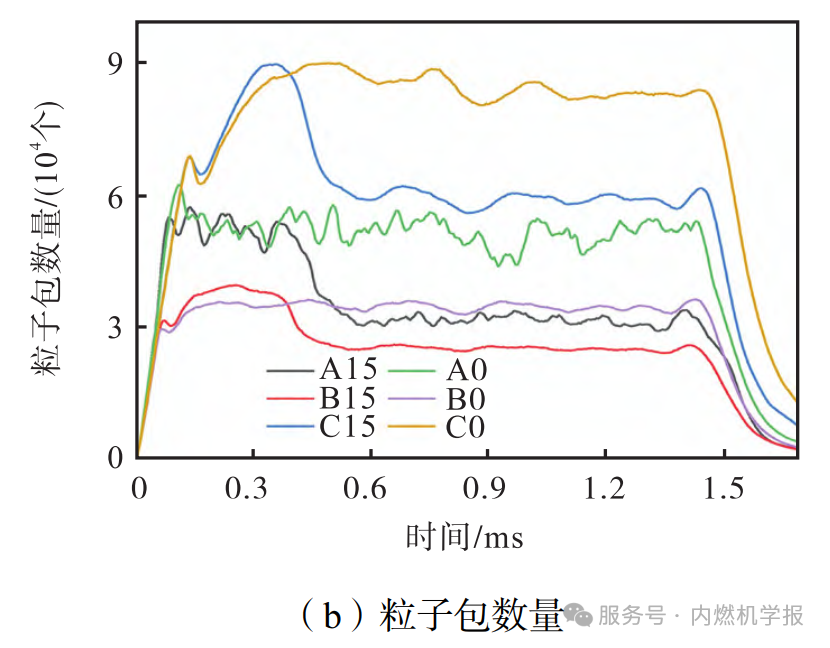

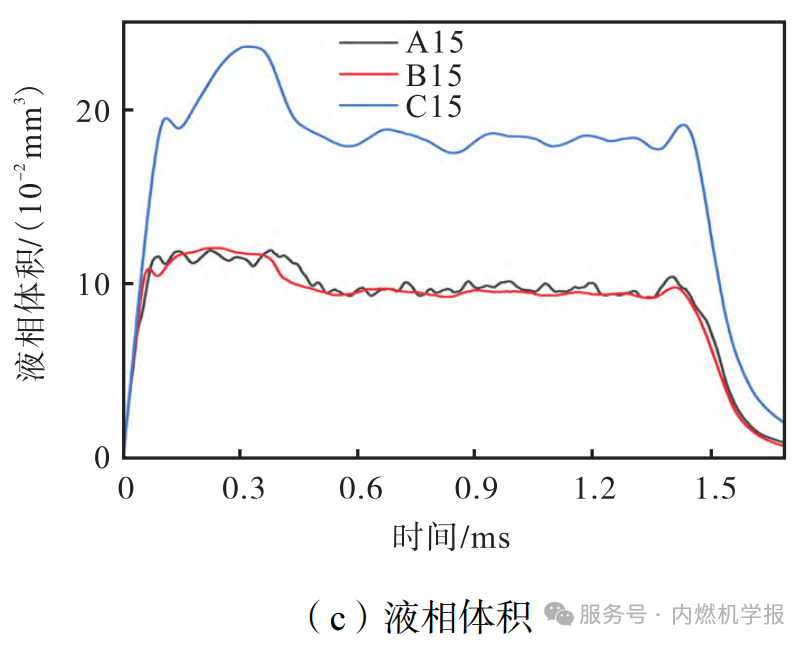

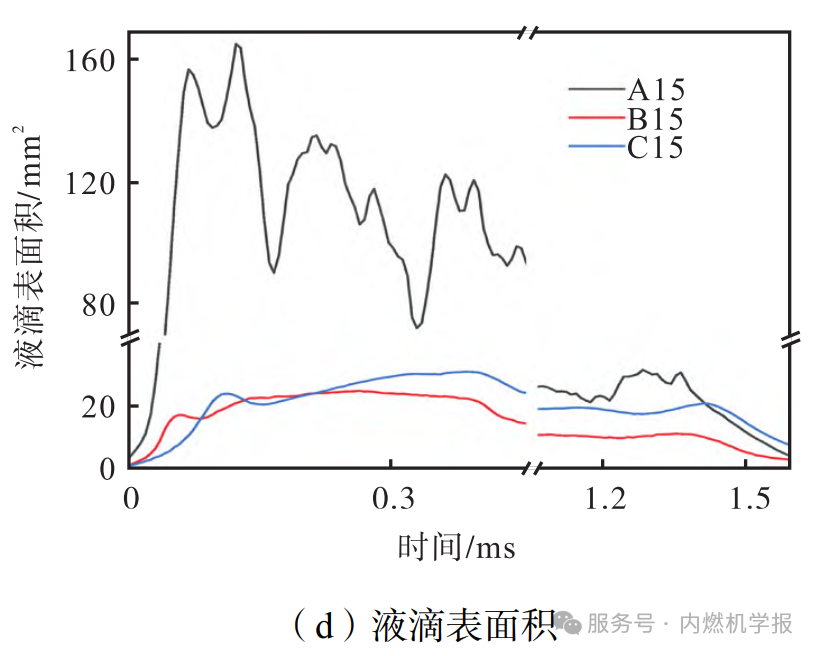

The droplet stability of high-viscosity fuel increases, the difficulty of crushing increases, the diameter of the crushed droplets increases, and the atomization quality deteriorates. SMD is an important indicator for evaluating atomization quality and can reflect the crushing and evaporation characteristics of fuel. The smaller the SMD, the better the degree of atomization. Figure 7 shows the liquid-phase spray parameters of different fuels. In Figure 7(a), the variation of SMD is proportional to the viscosity, and the maximum difference exceeds 85%. In the early stage of spraying, SMD was not related to whether an oxidation reaction occurred. Before ignition, SMD showed a slight upward trend, and after the spraying ended, SMD increased significantly. In order to greatly reduce the computing time and save computing resources, Converge introduces the concept of parcel in the process of solving the spray. Particle packets are composed of a series of fuel droplets with the same radius, velocity and temperature, etc. Therefore, the number of particle packets is the same as the types of droplet diameters in the spray field. For example, if there are x particle packets in the spray field, there will be x types of droplet diameters. Figure 7(b) shows the influence of fuel viscosity on the number of particle packets. According to the corresponding relationship between particle packets and particle diameters, it can be known that the type of droplet diameter is independent of the viscosity of HFO, but the types of diameters all decrease due to combustion. Meanwhile, the decrease rate of the droplet surface area is greater than that of the liquid phase volume, causing the SMD to increase. Therefore, the decrease in particle size types indicates that oxidation and combustion promote the fragmentation of large-diameter droplets and the evaporation of small-diameter droplets. The changing trends of liquid phase volume and surface area indicate that low viscosity before ignition is beneficial for droplet fragmentation. The droplet surface areas of fuel B and fuel C are close to those of SMD, but the liquid phase volumes differ significantly, and the particle size types of the two differ by more than 70%. Therefore, it can be inferred that the proportion of large-diameter droplets in the spray of fuel C is higher. Meanwhile, the larger droplet surface area enhances the interaction between the droplet and the environment, and the evaporation and entrainment effects are improved. Processes such as fuel viscosity, atomization and evaporation all affect the distribution law of droplet diameters. Figure 8 shows the droplet distribution and liquid phase morphology in the spray field at 0.1 ms and 0.9 ms. The radial diffusion ability of the liquid-phase spray is directly proportional to the viscosity. As the viscosity increases, the distribution pattern of the droplets becomes wider in the middle and narrower at the head and tail, and the maximum width of the liquid phase spray increases. The droplet distribution also reflects that the lower the viscosity, the lower the proportion of large-diameter droplets, and the better the dispersion at the front end of the liquid-phase spray. The ignition and combustion accelerated the evaporation of small-diameter droplets, reduced the SMD, and decreased the spray volume, proving the inference that the proportion of large-diameter droplets in the liquid-phase spray of fuel C was greater.

Figure 7 Liquid-phase spray parameters of different fuels

Figure 8 Liquid phase spray morphology

The section on "Combustion Characteristics" can be found in reference [1].

【 IV. Conclusion 】

(1) The spray penetration distances (LPL and VPL) of reactive and non-reactive sprays are different; The influence of ignition and combustion on VPL is significant and the influence effect is inversely proportional to the viscosity, while the influence on LPL is negligible and almost irrelevant to the viscosity. The spray morphology of high-viscosity HFO is "narrow and long", and the spray edges near the spray holes are "serrated".

(2) The distribution of SMD and droplet diameter is completely opposite to the influence of ignition and combustion. The rate of decrease of the droplet surface area is greater than that of the liquid phase volume, resulting in a slight increase in SMD under oxygen-containing conditions.

(3) The increase in the viscosity of HFO causes the delay of IT and the advance of the combustion phase. However, after ignition, the heat release rate slows down, the peak value decreases, and the distance between the flame and the nozzle shortens. The surface areas of droplet bundles of equal volume in IDS vary greatly. The surface area of low-viscosity HFO droplets fluctuates and the droplet stability is poor.

(4) When the viscosity of HFO increases, the distance between the gas-phase spray and the nozzle increases, and the tailing phenomenon of the flame is severe. The width of the flame head is inversely proportional to the viscosity of HFO, but directly proportional to the suction capacity of the spray for the ambient air. The viscosity of HFO does not affect the flame diffusion capacity and fuel consumption rate of steady-state combustion

The constant-volume combustion bomb system independently developed by Dian Shi Instruments can achieve precise combustion analysis under high-pressure - micro-pore injection conditions. By precisely regulating environmental parameters (such as temperature and oxygen concentration) and injection conditions, combined with multi-modal optical diagnostic methods such as high-speed streaking and chemiluminescence, it can quantitatively characterize the entire process of heavy fuel oil's spray penetration, droplet fragmentation, ignition delay and flame development. This system is particularly suitable for the research on the atomization mechanism of high-viscosity fuels. By changing the preheating temperature of the fuel, the viscosity parameters are decoupled, providing a key experimental basis for optimizing the combustion chamber design of Marine diesel engines.