更新时间:2024-08-13浏览量:111

Energetic materials are a class of compounds or mixtures containing explosive groups or containing oxidants and combustibles, which can independently undergo chemical reactions and output energy, and are an important part of the formula of military explosives, propellants and rocket propellants.

【project context】

A closed explosive device is a test system for studying the pressure change of energetic materials when they are burned at constant volume. In the static analysis of energetic materials, the test technique of closed explosive device plays a crucial role. The existing closed explosive device or closed blasting test system is usually installed in the professional blasting laboratory, which is not only bulky and expensive, but also not convenient for university laboratories to carry out the performance test of energetic materials. In order to successfully promote the performance test experiment of energetic materials, a university in North China urgently needs to match a partner that can provide a non-standard customized sealed explosive device.

【project context】

Dianshi Instrument has cooperated with University of Science and Technology of China and BYD Group respectively on space and space environment simulation device, heat island and fixed volume bomb, and has accumulated rich practical experience in the research and development, design and manufacturing of unconventional devices. There are many functional similarities between the closed explosive device and these large equipment. After comprehensive evaluation, the matching degree between Dianshi instrument and the school is very high, and with the joint efforts of both sides, the project quickly and successfully landed.

According to the person in charge of the Point stone instrument project department, the closed explosive device project encountered two major obstacles in the process of promotion: first, due to the epidemic containment, construction and logistics were affected; Second, at the same time, multiple projects cross, need to be coordinated.

"To ensure the smooth progress of the project, we have proposed a variety of solutions. First of all, make various plans to minimize the impact of potential risks and adverse factors; Secondly, we should stick to special personnel, assign responsibility to individuals, and focus on moving forward in an orderly manner." The head of the project department said.

【project outcome】

If the equipment is perfect, the Midas touch will turn the stone into gold. Dianshi Instrument is committed to providing practical, flexible and effective solutions for cooperative customers with professional technology. According to the actual needs of the school, we quickly tailored a simple and compact sealed explosion device. A few days ago, the project officially ushered in delivery! The new type of closed explosive device is suitable for studying the combustion law of energetic materials and gas generation law under constant volume condition. The energy containing assembly is ignited, the assembly releases gas and pressure on the pressure sensor, and the corresponding pressure-time (P-T) curve is obtained through data conversion.

【principal component】

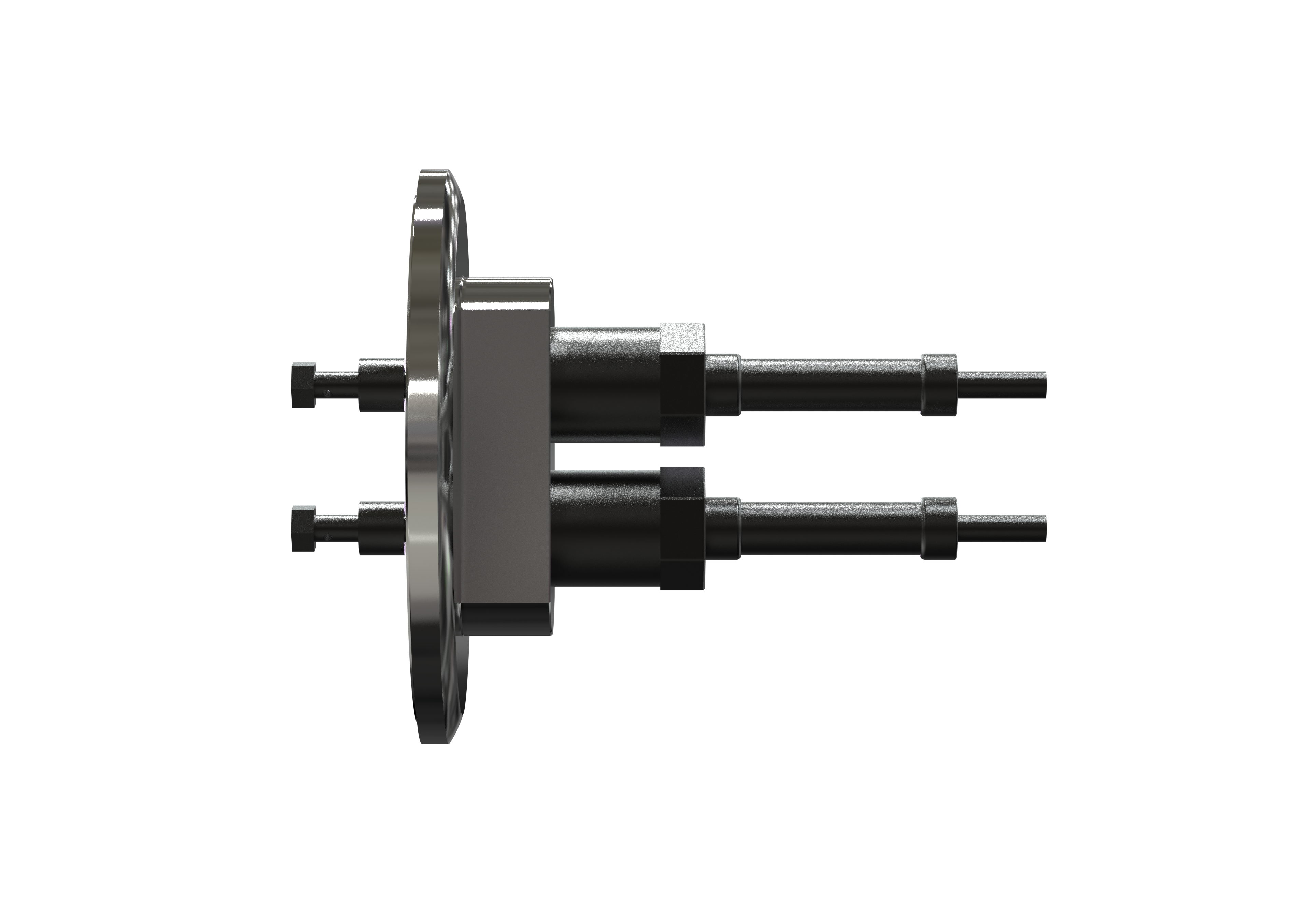

The new type of closed explosive device adopts functional modular design concept and integrated technology, which is mainly composed of four modules: tank module, ignition module, control module and signal acquisition module.

Tank module

Cavity shape: cylindrical cavity

Internal diameter: 30mm

Height: 30mm

Volume: 21ml

Composition: upper end cover, lower tank body, quick opening clamp, pressure sensor interface, ignition system interface

Pressure relief mode: Manual/automatic pressure relief

Fixing method: manual pressing device

Lgnition system

Composition: electric electrode, sealing bolt, ignition wire

Ignition wire: excellent nickel-chromium heating wire

Maximum heating temperature: 1000℃

Signal acquisition module

Composition: pressure sensor, data acquisition system

Pressure sensor: high frequency pressure sensor

Required acquisition system: corresponding acquisition system

Pressure sensor Probe: 200KHz piezoresistive pressure sensor

Pressure acquisition module: 250KHz asynchronous acquisition module

Lntelligent control module

Use: Control ignition, pressure relief

Ignition operation: remote operation

Manual pressure relief valve: can achieve tank pressure relief

The successful landing of the new closed explosive device project will provide strong technical support for the school to carry out the research on combustion gas products and combustion characteristics of energetic materials.