更新时间:2025-08-19浏览量:42

An Opposed Burner is an experimental device specifically designed for studying flame stability and combustion characteristics. Its fundamental design involves positioning two or more burners opposite each other, with their respective fuel and oxidizer jets impinging against one another. This creates a stable flame region between them, making it highly suitable for precisely controlled research under laboratory conditions.

Recently, a custom Opposed Burner product independently developed by Dianshi Instruments achieved its first overseas delivery, successfully reaching the world-leading National University of Singapore (NUS). This milestone signifies that Dianshi's accumulated expertise and achievements in the field of engineering thermophysics research equipment have gained recognition from top-tier international academic institutions.

The implementation of this project will strongly support scientific research in engineering thermophysics fields such as flame stability and propagation characteristics, turbulent combustion, pollutant formation mechanisms, and high-temperature corrosion and pyrolysis of materials, thereby aiding the development of new combustion technologies. This successful delivery will also enhance the international visibility and brand image of Dianshi's custom research equipment, helping Dianshi Instruments play a greater enabling role in the field of engineering thermophysics both domestically and internationally.

1. Product Structural Design

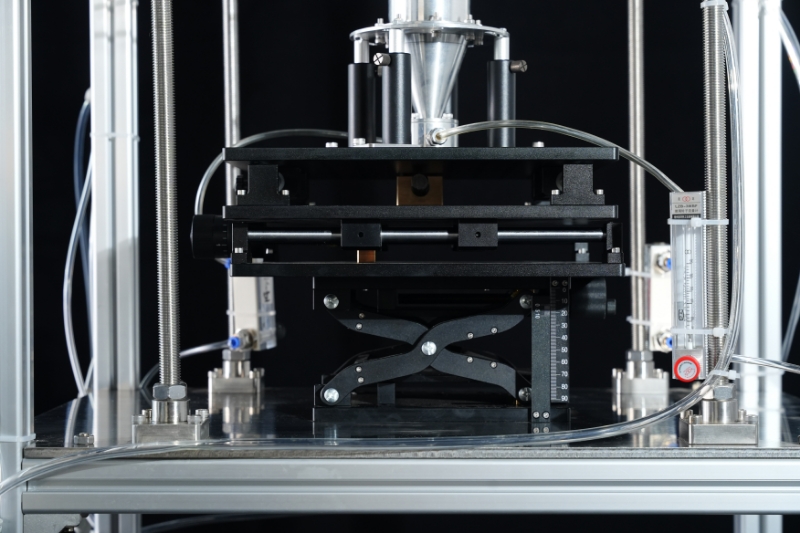

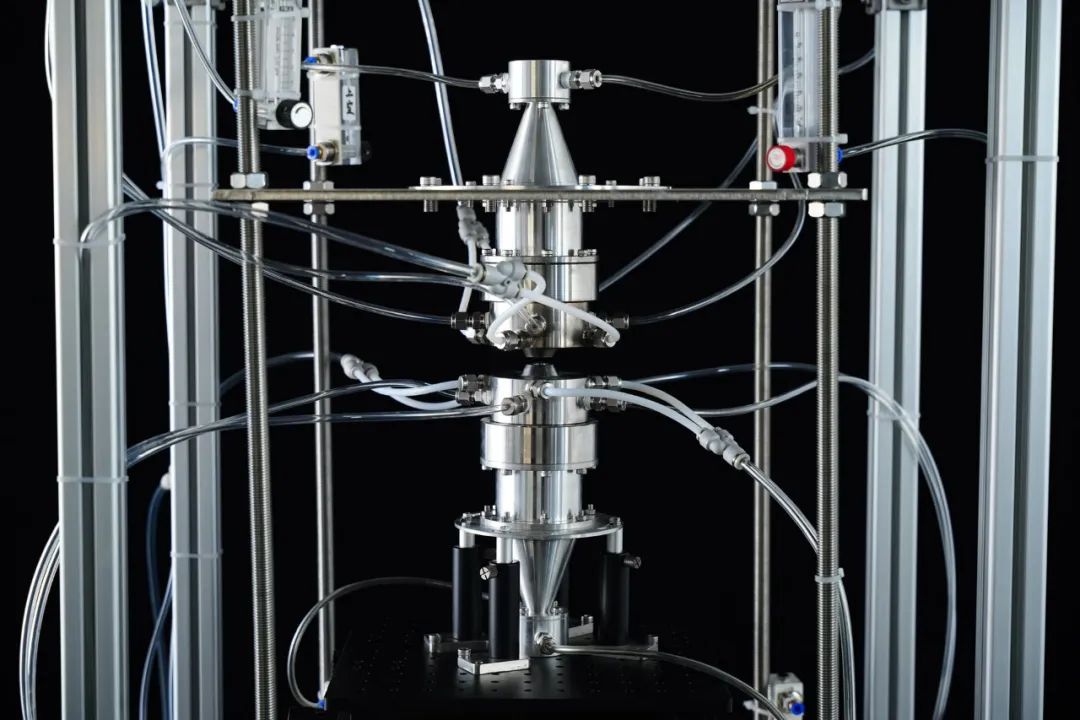

The Opposed Burner includes a frame, Z-axis lifting platform, XY-axis mobile worktable, adjustment rods, lower burner, upper burner, upper burner adjustment mechanism, and water chiller.

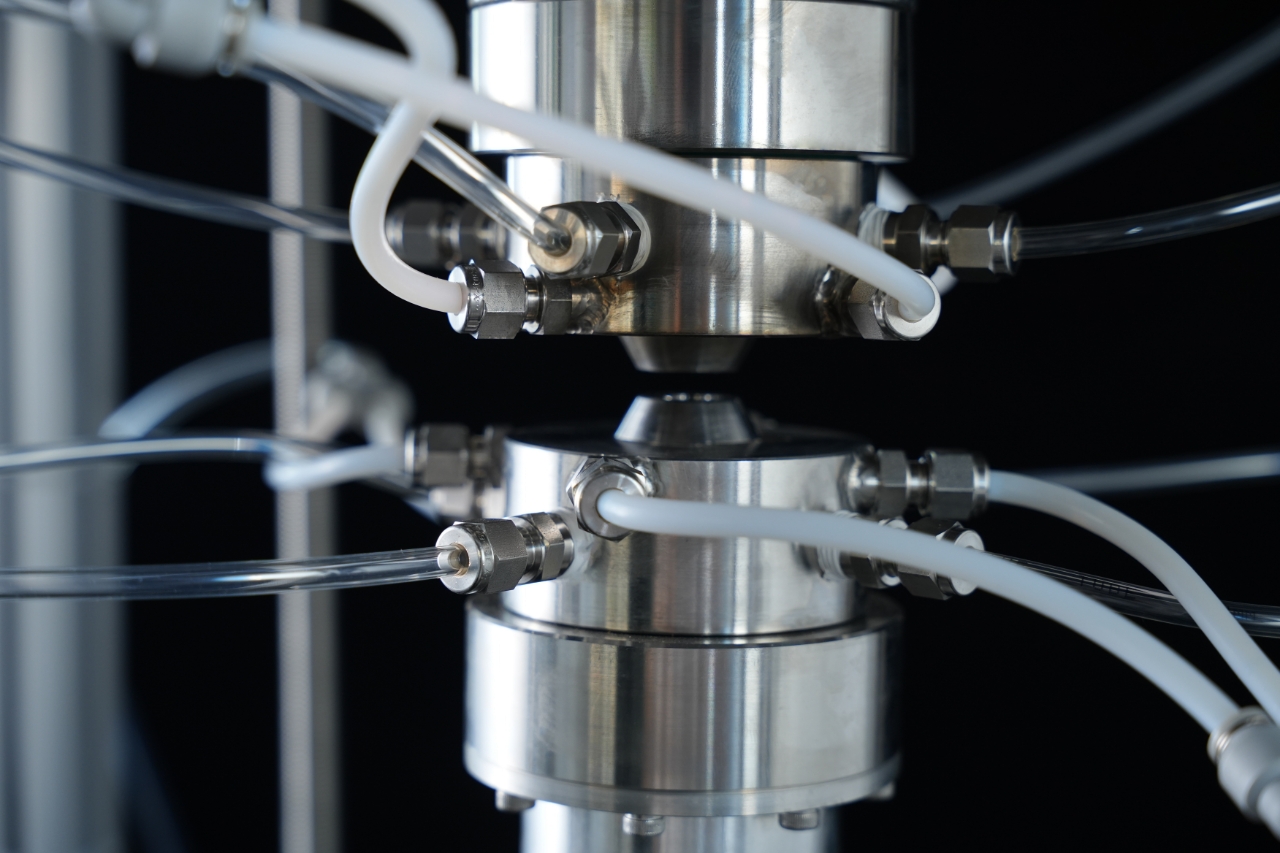

Each burner includes an oxidizer inlet, fuel inlet, shield gas inlet, cooling water inlet, oxidizer/fuel nozzle, and shield gas nozzle.

Oxidizer Injector and Gaseous Fuel Injector: The oxidizer gas injector and gaseous fuel injector are coaxially arranged along the vertical direction, with their injection ports facing each other vertically (one above, one below).

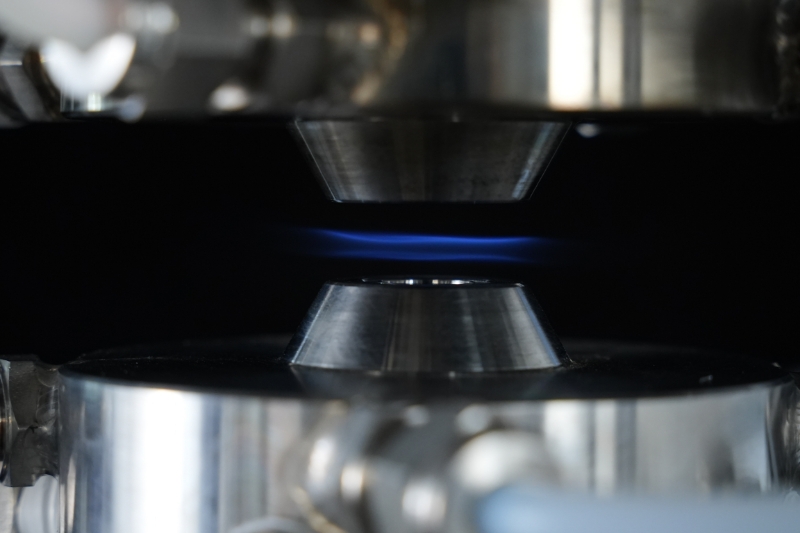

The oxidizer-end nozzle and the fuel-end nozzle have identical structures. The oxidizer-end nozzle features a central injection channel whose inner diameter gradually decreases from the inlet end to the outlet end.

The oxidizer-end nozzle incorporates a shield gas injection chamber and a water cooling chamber, both coaxially arranged around the injection channel. The shield gas injection chamber, located outside the injection channel, has an annular outlet. The water cooling chamber is positioned outside the shield gas injection chamber.

The minimum distance between the oxidizer-end nozzle and the fuel-end nozzle is 5mm ~ 20mm.

The oxidizer inlet connects to the oxidizer supply pipeline. The fuel inlet connects to the gaseous fuel supply pipeline. The shield gas injection chamber connects to the shield gas supply pipeline via multiple inlet holes on its side. The water cooling chamber connects to the water chiller pipeline via multiple sets of inlet/outlet holes.

2. Functions and Advantages of the Opposed Flame Burner

1. The Opposed Flame Burner overcomes the limitation in existing technology where forming a controllable unsteady flame is difficult. It provides a stable unsteady opposed flame with highly controllable velocity boundaries.

2. The gradually decreasing diameter of the injection channel in the Opposed Burner nozzles accelerates the ejected gas within the nozzle section, effectively increasing the impingement velocity of the gases. The curved wall structure ensures uniform velocity distribution at the outlet.

3. The opposing jets of fuel and oxidizer streams cause their diffusion and mixing to occur at a specific point between the two nozzles, resulting in the formation of a thin flame with a one-dimensional structure.

4. An annular shield gas injection chamber is integrated around the nozzle to prevent interference from ambient air and inhibit the formation of secondary diffusion flames.

5. To cool the hot combustion product gases and prevent the fresh oxidizer stream from being heated, a water cooling chamber is incorporated into the nozzle, with cooling water continuously circulated through it.

Based on the above design, Dianshi Instruments' Opposed Burner can:

* Form a thin flame with a one-dimensional structure.

* Generate an unsteady flame with highly controllable outlet velocity boundaries.

* Enable precise observation of the effects of different waveform conditions on soot formation in opposed combustion.

3. Application Significance

Opposed Burners are vital tools for fundamental and applied research in combustion science. The custom Opposed Burner product from Dianshi Instruments can provide crucial technical support for improving combustion efficiency, reducing pollutant emissions, and developing new materials. It will empower researchers to develop more efficient and environmentally friendly combustion technologies.